Pvc Processing Aid AC-175

PRODUCT DESCRIPTION

Provides excellent hot metal release characteristics, reducing sticking and plate-out, without affecting the clarity or compatibility of the vinyl (PVC) itself or of the finished parts.

USES

- Improve hot metal release of PVC during melt processing

- All methods of rigid PVC melt processing including calendering, extrusion, foam extrusion, and injection molding

- Reduce equipment downtime for cleaning

- Improve flow to edges of sheets and corners of profiles

- Provide good release to prevent tearing at such locations

- Improve surface tension for printing on sheet through reduction in waxy external lubricants

KEY BENEFITS

- Excellent hot metal release characteristics during PVC processing

- Reduces sticking and burning, friction, and shear-burning

- Limits plate-out

- Improves the PVC article appearance

- Greatly extends the time between needing to shut down equipment for cleaning

- Reduction in use of waxy external lubricants that are prone to plate-out and blooming to the surface

- Does not bloom with time

- Does not adversely affect the clarity of the vinyl (PVC) in clear applications

- Effective in all conversion methods of rigid PVC melt processing

Application

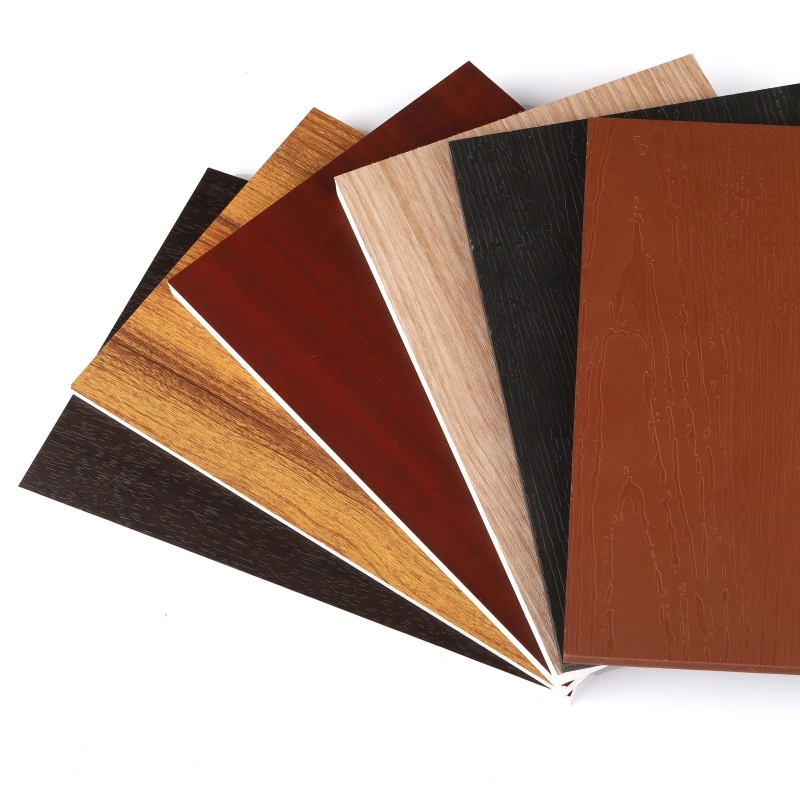

PVC sheet

PVC Foam Board

PVC profiles